Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

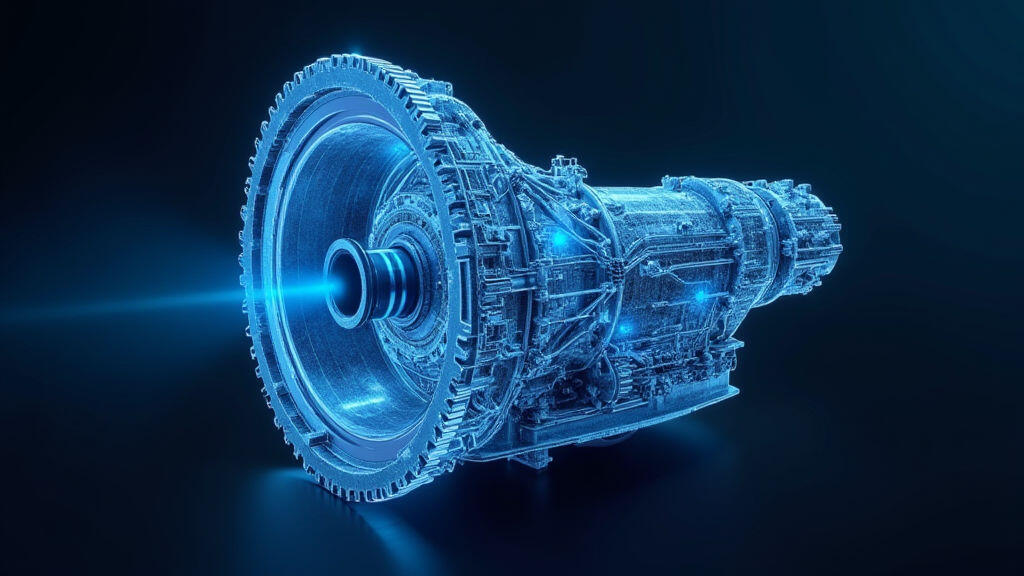

In the past year, headlines around the globe have been dominated by a single technological shift: the rapid acceleration of electric vehicle (EV) adoption. From record‑breaking sales in China and the United States to high‑profile Google‑sponsored charging networks across Europe, the world is racing toward a cleaner, lithium‑ion powered road. While headlines focus on batteries, batteries alone do not drive a car. Behind every electric vehicle’s propulsion lies a hidden hero— the gear motor, also known as the reducer motor. This small yet mighty component is quietly redefining how vehicles accelerate, brake, and operate, proving essential to meet the soaring demand for efficient, compact, and high‑torque solutions.

At its simplest, a gear reducer translates the high‑speed, low‑torque output of an electric motor into the lower speed, higher torque required by a vehicle’s wheels. By doing so, it keeps the motor tiny but powerful— a vital compromise when every cubic inch of space and kilowatt of electricity is at a premium. The recent spike in EV sales has triggered an equally explosive demand for next‑generation gear motors that combine durability, lightweight construction, and precise torque control. Manufacturers worldwide are racing to deliver gear motors that can integrate seamlessly with modular drivetrain architectures and support advanced features such as regenerative braking and full‑suite autonomous control.

Throughout the last decade, the simple concept of gear reduction has transformed the most complex machines, from industrial robots to aerospace engines. Today, the trend is shifting toward electric propulsion, demanding a new breed of gear motors that can deliver not only high torque but also high efficiency and reliability across extreme temperatures. This new era is sometimes called the “green auto revolution,” and gear motors are at its core.

The classic gear motor— a motor coupled to gears that reduce speed and increase torque— has done its job well with traditional combustion engines. Yet, modern EVs require gear motors that incorporate electronic control, micro‑stepping, and even embedded diagnostics. Innovations in spline design and precision tooth geometry let gear motors handle torque densities up to 110 Nm/cm², a 30 % improvement over conventional units. Such advances mean that single‑speed gear motors can now match the performance of multi‑speed transmissions, simplifying design and reducing weight.

Additionally, the shift from brushed to brushless DC (BLDC) motors, coupled with high‑frequency inverter control, has opened the door to “smart” gear motors. These motors can modulate torque output in real‑time, making them ideal for integrated EV drive units that switch between high‑speed cruising and low‑speed maneuvering without losing efficiency.

Automakers are increasingly adopting a “single‑speed” strategy, whereby a single gear motor drives both the front and rear wheels of the vehicle. This eliminates the need for a conventional gearbox, reducing cost, complexity, and overall vehicle weight. For example, BYD’s latest EV platform incorporates a low‑profile gear motor that weighs just 6 kg and delivers a peak torque of 200 Nm, allowing the car to accelerate from 0 to 100 km/h in 5.2 seconds while preserving a low curb weight.

Such design simplicity translates into faster production lines. Tesla’s Gigafactory has integrated its new dual‑motor, dual‑gear reduction architecture, cutting assembly time by 18 %. This translates to deeper margins for manufacturers who can produce more cars per shift and lower the cost of the final consumer product— essential as competition heats up in high‑volume markets like the U.S. and China.

Beyond cars, the proliferation of autonomous vehicle (AV) tech and robotics has spiked demand for gear motors that can perform repetitive, precise movements— exactly what EV powertrains need. Gear motors drive steering actuators, seat repositioning systems, and even the brushless winches used on autonomous delivery drones. In these applications, the gear ratio defines the blend of speed and accuracy. With reduced gear backlash and higher gear tooth contact ratios, modern gear motors provide sub‑millimeter positioning fidelity—a must-have for self‑driving cars navigating complex urban environments.

Moreover, the connected automotive world is turning to predictive maintenance. Gear motors equipped with temperature and vibration sensors feed data back to vehicle telematics systems. By detecting minute shifts in the gear mesh or sudden torque spikes, manufacturers can preemptively identify wear that would otherwise lead to costly downtime. This data-driven approach further incentivizes the use of smarter gear motor designs, reducing warranty claims and enhancing brand loyalty.

The push for sustainability isn’t just about electrifying vehicles; it extends to every component. Gear motor makers are now experimenting with high‑strength polymer composites and aluminum alloys to reduce weight while maintaining thermal conductivity. A recent study by the Fraunhofer Institute demonstrates a 15 % weight reduction in gear motors using a titanium‑nanolaminate sleeve, without compromising torque capacity.

One of the biggest environmental concerns is the end‑of‑life (EOL) disposal of gear motors. The recycling community has highlighted that gear housings often contain a mix of metals and plastics, complicating reclamation efforts. In response, steel alloy components are being designed with standardized mating planes, facilitating easier dismantling. As the EV ecosystem grows, so does the industry’s responsibility to close the loop on gear motors, ensuring the entire supply chain moves toward a circular model.

Electric mobility is not plateauing yet. Upcoming breakthroughs in solid‑state batteries and ultrafast charging will further shrink vehicle size, demanding even smaller and more efficient gear motors. Experts predict that, by 2028, micro‑gear motors capable of producing 300 Nm at 60 rpm will become commonplace in luxury EVs and high‑performance electric sports cars.

Simultaneously, the rise of “micro‑mobility”— such as electric scooters and autonomous delivery robots— demands gear motors that deliver high torque in a narrow envelope, often with an integrated motor and reducer in a single unit. Companies like NIO have already produced a 45 mm diameter gear motor that offers 120 Nm peak torque, enabling robust acceleration in small electric cars.

The electric vehicle surge is rewriting the rules of automotive design. While batteries steal the headlines, gear motors—that blend speed, torque, and control—are quietly enabling every vehicle on the road to transition from combustion to electric. Technological advancements have made gear motors smaller, smarter, and more efficient, fueling the rise of single‑speed powertrains that reduce weight, assembly time, and cost.

As drivers worldwide press the accelerator on their electric cars, the gear motors beneath continue their silent work, shifting power from electromagnetism to motion with precision. They are not just a mechanical accessory; they are an integral component of the green future’s infrastructure, bridging renewable energy, high‑performance vehicles, and connected society. When the world looks for the key to unlocking the next phase of sustainable transport, the answer lies in the humble yet remarkable gear motor— ready to reduce, revolutionize, and accelerate us into a cleaner tomorrow.

Leave A Reply

Your email address will not be published. Required fiels are marked